Performance & Angle sensor technology

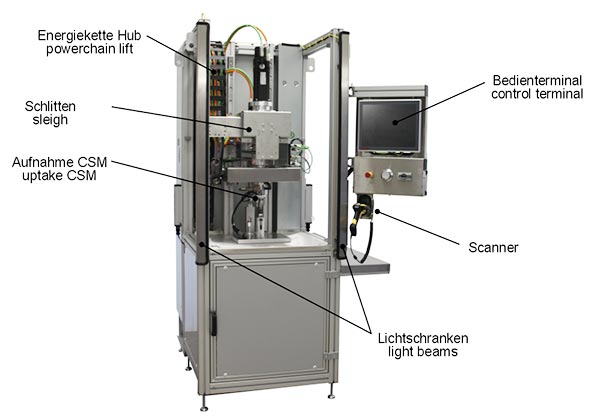

End Of Line-Function Test Rig

Product details:

Inspection and final acceptance of performance characteristics of steering wheels with independent actuators.

The end of line-function test rig is used for testing and final acceptance of the performance characteristics of steering wheels with independent actuators.

The test items are tested in an automatic runtime environment for both performance and internal angle sensor technology. For this purpose, the test rig has an external load machine for simulating steering torques.

Test Item Control

The test rig is controlled by an industrial PC via an EtherLab system. The signal acquisition and control takes place in a 1 ms cycle. The control is additionally equipped with a CAN-FD interface. The test rig is operated by a multi-touch panel.

The following control unit-specific functions are used:

- communication according to ISO 11898-1

- status-dependent residual bus simulation on DBC basis

- communication according to IsoTP ISO15765-2

- communication according to UDS ISO 14229

- reflashing of the control ECUs via UDS

- configuration of the test item via UDS

- error handling of the test item via UDS

- time synchronization of the remaining bus signals to the EtherLab system

Testing Process

The trained operator identifies the test item with a hand scanner via a QR code. A type-specific test sequence and configuration is automatically selected by the test rig via a production control system.

The test procedures and configurations can be defined independently by the customer. During the test sequence, the operator is informed about necessary interactions, e.g. insertion, contacting of the test item.

After completion of the test, the results are stored in a customer production database. Furthermore, test item-related log and result files are automatically stored.

After completion of the test, the results are stored in a customer production database. Furthermore, test item-related log and result files are automatically stored.

Technical data:

| dimensions: | L = 1250 mm W = 1500 mm H = 2100 mm |

|---|---|

| mass: | ~500 kg |

| supply: | 400 VAC |

| electrical installed power: | 10 kW |

| sound pressure level: | 70 dB |

| operating pressure (pneumatic): | 6 bar |

| ambient temperature range: | 20° C to 30° C |

Your contact person:

| Dipl.-Ing. (FH) Andreas Stewering-Bone | |

|---|---|

| Phone: | +49 (0)2 01 – 3 60 14-0 |

| E-Mail: | |