Test of hydraulic components

Pressure Fatigue Test Rig

Product details:

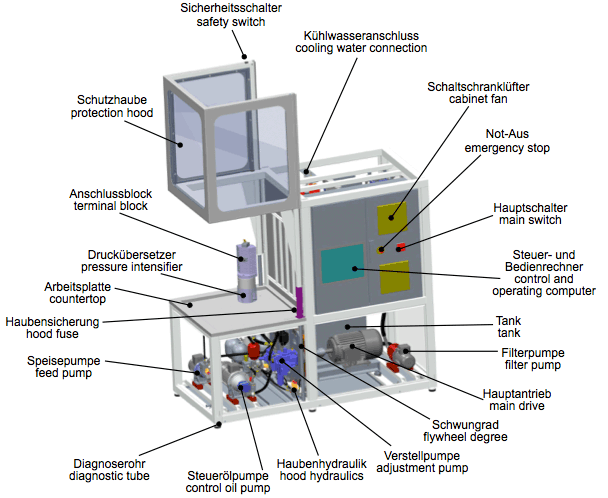

Pressure Fatigue Test Rig to test hydraulic components according to DIN EN ISO 8434.

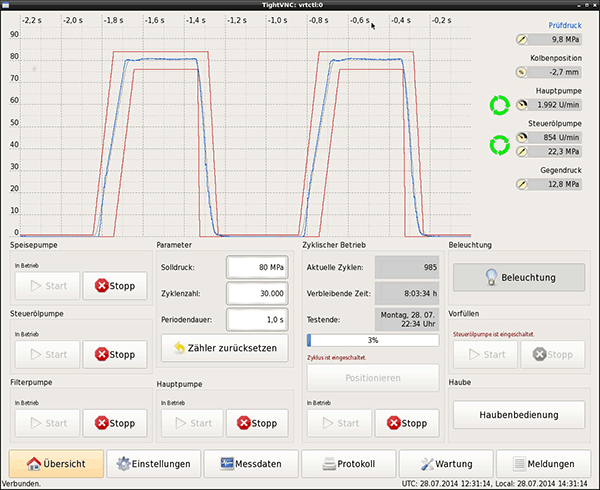

The Pressure Fatigue Test Rig is designed for the test of hydraulic components according to DIN EN ISO 8434. During these tests the hydraulic components are loaded with a defined cyclic pressure profile up to a maximum pressure of 1200 bar. The pressure load is repeated several million times with a cycle frequency of about 1 Hz.

Operating principle

A lot of energy is used for pressure generation. In conventional test rigs, this energy is lost after each pressure pulse and must be dissipated in the form of heat via a cooler.

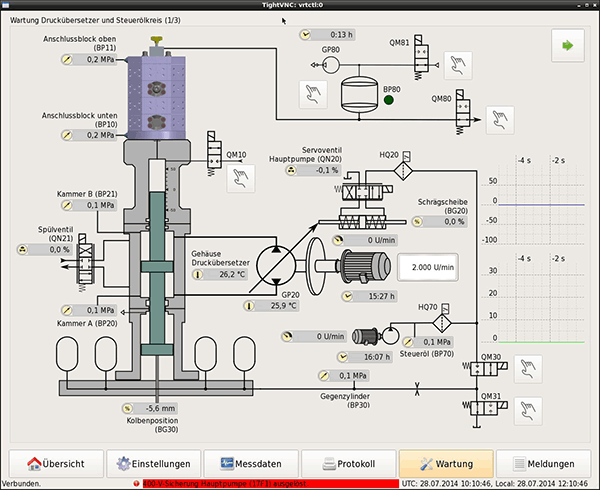

In the concept implemented here, part of the energy stored in the compressed oil is recovered, so that the test rig only consumes a fraction of the energy.

To achieve high test pressures of up to 1200 bar, a pressure intensifier is used. The pressure intensifier in this test rig is driven by an adjustable pump in a closed circuit. The pressure is controlled servo-hydraulically via a digital pressure regulator, which is integrated in the test rig automation.

Special features:

- adaptive pressure control, which automatically adapts to the volume and stiffness of the test objects

- vacuum unit for venting and filling the test objects

- tracking of the inspection process via the Intra-/Internet

- web-supported protocol generation

Technical data:

| maximum pressure: | 1200 bar |

|---|---|

| maximum test item volume: | 1 l |

| mass: | 2500 kg |

| dimensions: | L = 2500 mm W = 1200 mm D = 2300 mm |

| electrical installed power: | 25 kW |

| test cycle frequency: | 1 Hz |

| max. sound pressure level: | 75 dB |

| max. heat dissipation into the cooling water: | 25 kW |

Your contact person:

| Dr.-Ing. Siegfried Rotthäuser | |

|---|---|

| Phone: | +49 (0)2 01 – 3 60 14-0 |

| E-Mail: | |