Determination of the properties of rotating, dynamic seals

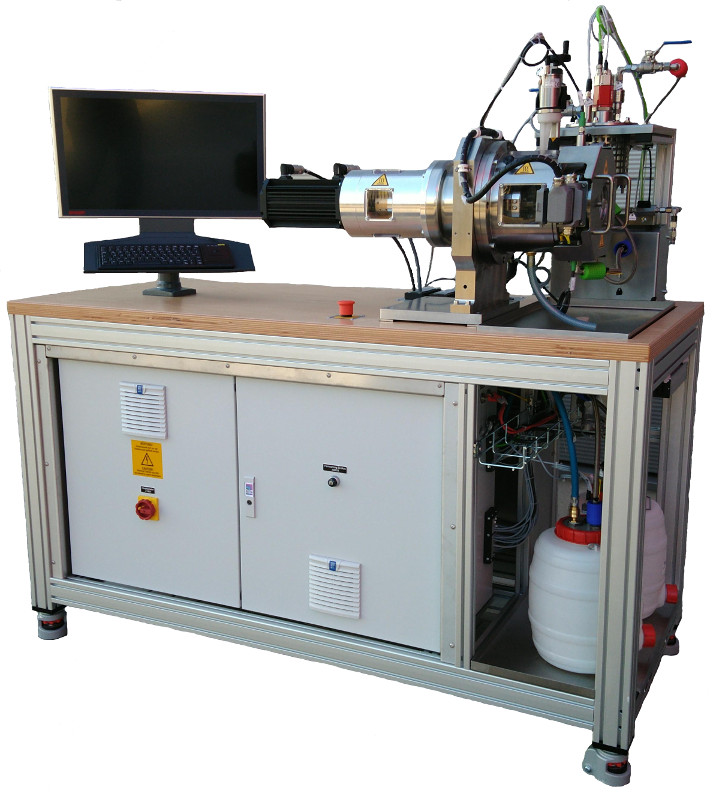

Sealing Test Rig

Product details:

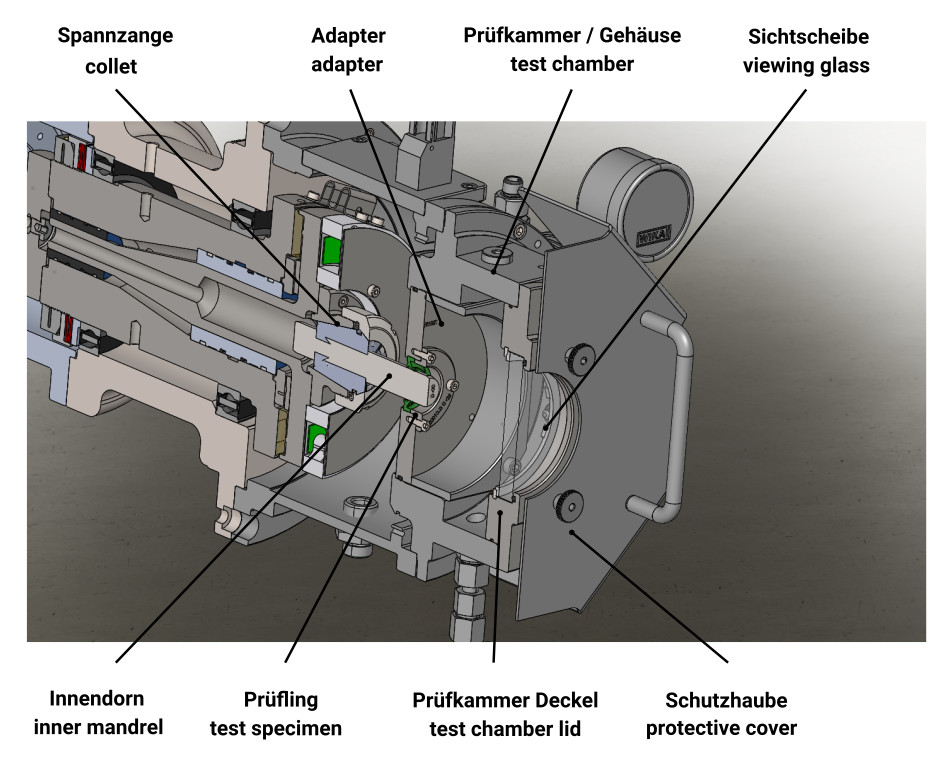

This test rig is used to investigate the wear, leakage and friction behavior of dynamic seals - in particular radial shaft seals.

This test rig is used to investigate the wear, leakage and friction behavior of dynamic seals. The adjustable test parameters are the differential pressure, the speed and the temperature profile. The test bench can work with different media also in the wake-free continuous operation. The high-precision torque measurement is carried out with a rotating torque sensor.

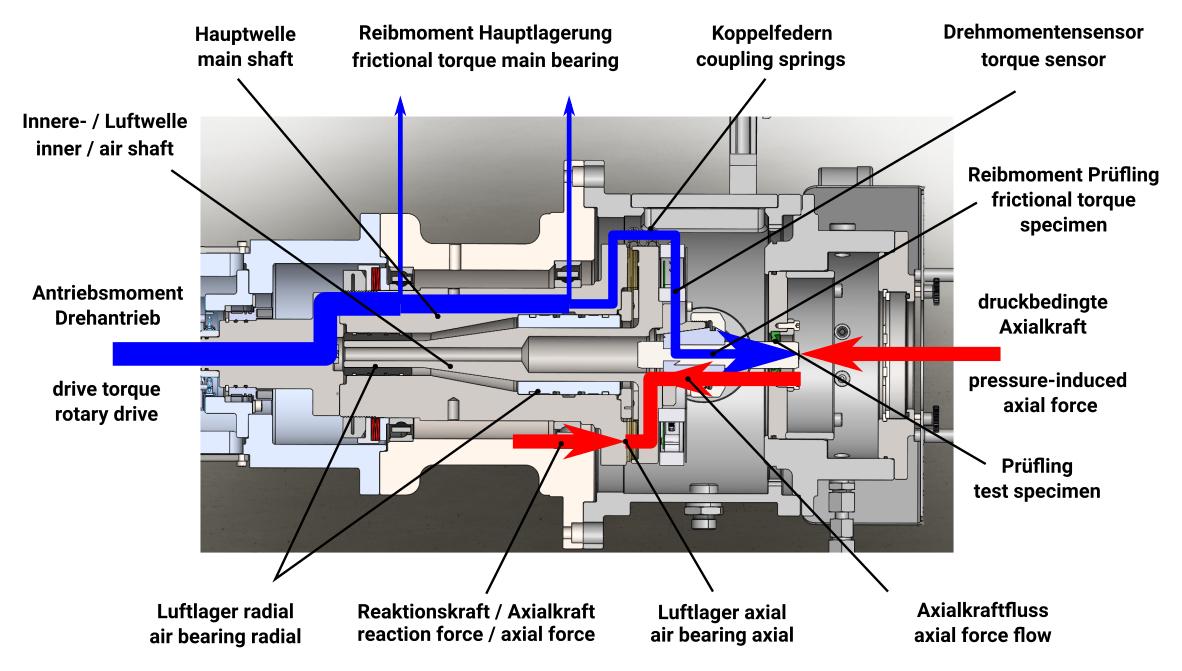

The pressurization results in a high axial force on the test shaft. This is decoupled by a frictionless air bearing. This enables the torque measurement with a very high accuracy with simultaneous high axial load.

Leakage measurement is carried out by two independent high-precision volume flow sensors.

The test stand is equipped with an exhaust system to allow the use of flammable or hazardous test media.

With the help of a laser-guided infrared temperature measurement, the seal lip temperature is continuously monitored.

Termination conditions for a test can be configured flexible to ensure wake-free operation.

During a test run, all the relevant test variables, such as e.g. frictional torque, rotational speed, leakage and temperatures are permanently recorded at high frequency.

Test data is stored with the configuration data in a database and is available company-wide via a web frontend.

Technical Data:

| speed: | 30 - 3000 1/min |

|---|---|

| differential pressure: | bis 0.6 MPa (6 bar) |

| fluid temperature: | 20°C – 100°C |

| torque measurement: | +/- 2 Nm |

| accuracy of torque measurement: | 0.01 Nm |

| leakage measurement: | 0 - 1000 g/h |

| accuracy of leakage measurement: | 1 g/h |

| Test items | dynamic seals lip seals or comparable type |

| shaft diameter test item: | 0 - 80 mm |

| mounting diameter test item: | 15 - 100 mm |

your contact:

| Dr.-Ing. Wilhelm Hagemeister | |

|---|---|

| Phone: | +49 (0)2 01 – 3 60 14-0 |

| E-Mail: | |

| Dipl.-Ing. (FH) Andreas Stewering-Bone | |

|---|---|

| Phone: | +49 (0)2 01 – 3 60 14-0 |

| E-Mail: | |