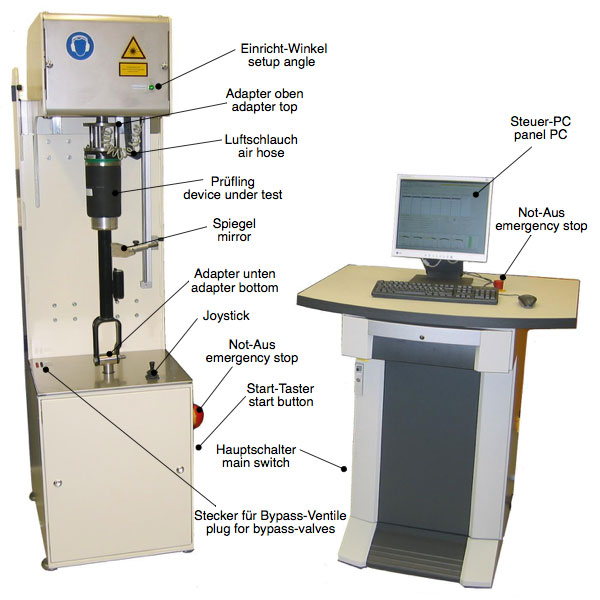

Test rig for air spring struts and PKWs

Spring Strut Test Rig

Product details:

Mechanical and geometrical measurement of air spring struts for passenger cars.

Air spring struts for passenger cars are measured mechanically and geometrically with the spring strut test rig. The test rig is designed to test prototypes according to defined test procedures and to document the results. These test sequences allow a statement about the further usability of the spring struts. The automated measuring task is divided into two parts (determination of the spring characteristic curve and orbital and radial runout tests), which can also be performed separately.

Measuring Unit

Air spring struts can be filled in a defined way on the test rig. The measurement takes place by stretching or compressing the spring struts. The force between test item and test rig is measured continuously. From the force-stroke-curve further values are determined in the following. These include among others: hysteresis, the maximum compression and rebound travel and the spring stiffness at defined positions.

Furthermore, manufacturing tolerances can be checked automatically with a high-precision laser triangulation sensor, whereby the suspension strut rotates around its vertical axis during measurement.

Test Item Control

An industrial PC integrated in the control cabinet with a Linux operating system and suitable interface cards handles the sequence control and control tasks. During the realization of the test rig, special attention was paid to the intranet-supported visualization, documentation and administration of the measurement results, which was developed in close cooperation with the client.

Technical data:

| dimensions: | H = 1920 mm (entrenched), W = 630 mm, D = 800 mm |

|---|---|

| mass: | 800 kg |

| supply: | 400 V / 16 A |

| maximum compression force: | 25 kN |

| maximum traction: | 20 kN |

| speed of the test procedure during the test: | 2 mm/s |

| speed of the test procedure to set up: | max. 20 mm/s |

| accuracy class of force measurement: | 0,1 |

Your contact person:

| Dr.-Ing. Siegfried Rotthäuser | |

|---|---|

| Phone: | +49 (0)2 01 – 3 60 14-0 |

| E-Mail: | |